THE ART OF LEADERSHIP

“The only way to win is to learn faster than anyone else.”

Eric Ries

Win Through Learning Speed, Not Guesswork

Markets shift, customers change their minds, and competitors copy features. In that world, leadership isn’t about having perfect answers; it’s about building a Team that learns faster than the uncertainty. Learning speed comes from curiosity, humility, and a willingness to test assumptions rather than defend them.

Treat every initiative as a hypothesis. Define what you believe, what would prove you wrong, and the smallest experiment that can generate evidence. Put a cadence around it: weekly metrics reviews, short retros, and clear decision owners who can pivot without waiting for permission. Reward people for surfacing bad news early, because it saves time and money.

Give context rather than control. Share the goal, constraints, and what “success” looks like, then let people choose the method. Keep the loop tight: ship something small, measure real behavior, learn, and adjust. You become harder to beat not because you never fail, but because you learn faster.

Run one 7-day experiment, review metrics, and decide to scale, tweak, or stop.

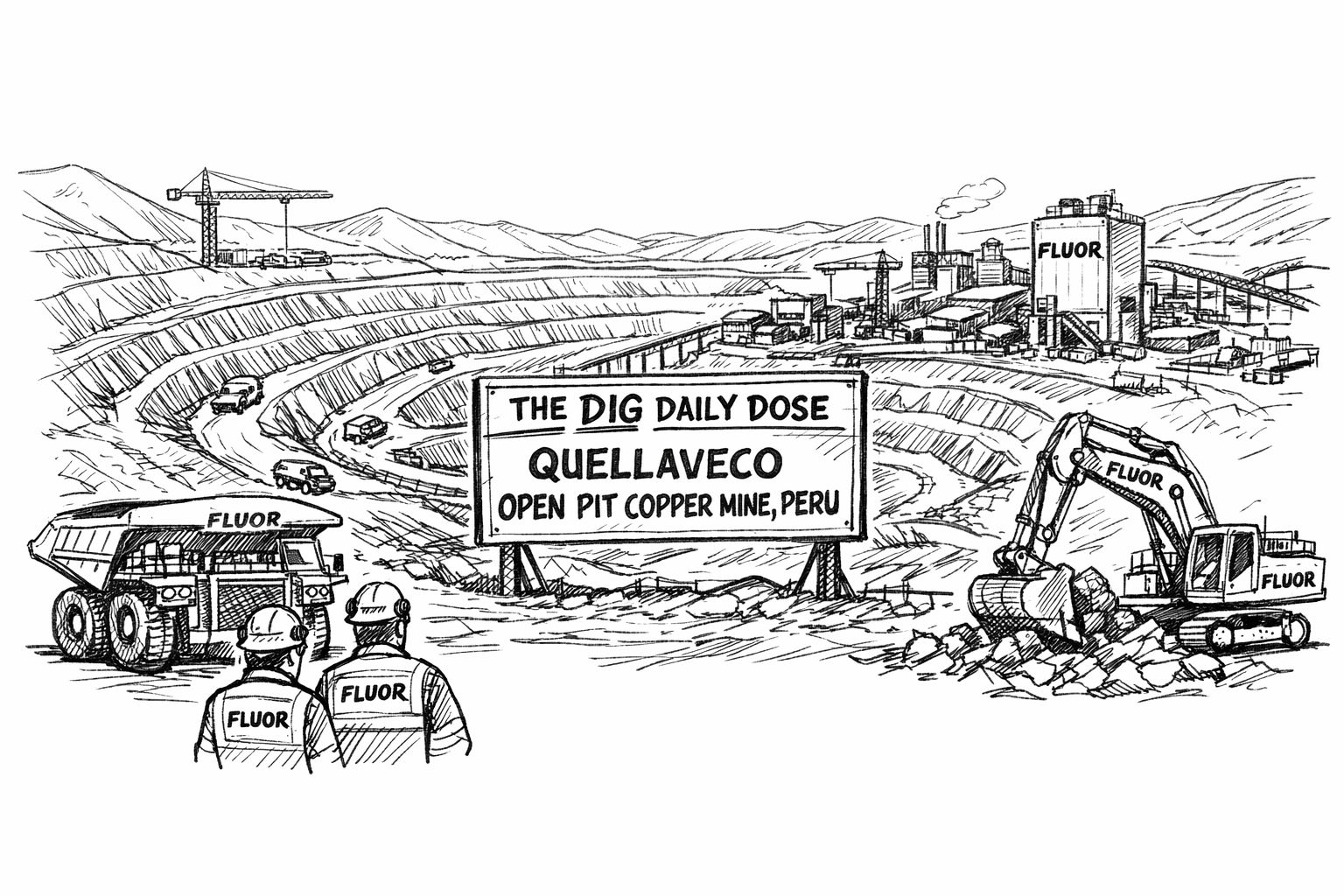

COMMERCIAL CONSTRUCTION

Can sustainability become a project discipline, not just a promise?

Fluor frames its approach as sustainability-guided governance: meet client needs while operating in socially, economically, and environmentally responsible ways. That turns ESG from a report into a decision filter for safeguarding the environment, conserving energy, protecting lives, and strengthening the economies and social structures around projects.

The company builds guardrails around that intent. Community relations focuses charitable efforts on four areas: education, public health and critical human needs, economic development, and the environment. Compliance and ethics are treated as proactive risk work, aiming to move beyond laws and regulations by monitoring evolving risks and benchmarking best practices.

Governance and HSE connect values to execution. Governance standards and strong leadership support sustainability strategy, goal-setting, reporting, transparency, and accountability. Health, safety, and environmental commitments extend care to workers, offices, and surrounding communities, because it is right and because it drives client excellence. A sustainability timeline reinforces the long view: habits, not slogans, endure.

Fluor treats sustainability, ethics, governance, and HSE as one execution system.

INFRASTRUCTURE INDUSTRY

How do regional pipelines secure easements without inflating bid risk?

Construction has begun on WaterLink, a roughly 30-mile pipeline extension that will expand Lake Michigan drinking water service from Naperville to Montgomery, Oswego, and Yorkville, with delivery projected as early as 2028. The project follows years of demand studies and a decision that the Ironton Galesville aquifer will not meet long-term needs.

For contractors, the work is classic large-diameter utility construction with an uncommon level of coordination: securing easements, sequencing traffic control, crossing existing utilities, and planning trenchless segments where disruption would be costly. Material lead times for pipe, valves, and fittings, plus restoration standards for roads and trails, can turn small delays into weeks of lost production.

The winning play is to manage it like a program, not a single job. Lock right-of-way and utility agreements before mobilization, standardize details across segments, and use rolling QA to close out each reach with survey-verified as-builts. When owners pay promptly for accepted quantities and maintain tight change control, crews stay moving, and the pipeline reaches customers without a claims spiral.

Lock easements and utility crossings early to keep crews moving.

RESIDENTIAL RESEARCH

Will tighter permitting requirements speed up builds or stall them at renewal?

New York City’s Department of Buildings is tightening how structural permits flow through DOB NOW. Starting February 2, 2026, a separately filed alteration tied to a new building, enlargement, or change in use will be subject to new checks before a structural, foundation, or earthwork permit is issued or renewed.

At the same time, sidewalk shed permits issued or renewed on or after that date will expire every 90 days and will not auto-renew. That turns temporary protection into a recurring administrative sprint: missed renewals can halt work, trigger penalties, and force rescheduling of inspections and trades.

Builders can reduce risk by consolidating filings where possible, mapping each job-number dependency early, and assigning a single owner to track DOB NOW status changes. Build a renewal calendar, keep progress photos and narratives ready for the new shed questions, and budget time for determination requests when earthwork or foundation scopes are split into separate filings.

Track permit dependencies and renewals to protect your critical path.

TOOLBOX TALK

Safe material stacking and storage to prevent collapses

Morning, crew. Before production ramps up, we are staging materials properly. Stack, rack, block, or interlock every tier so it cannot slide, fall, or collapse. Keep aisles and walk paths clear for safe travel and equipment movement. Do not store materials near floor openings or edges. If you see a leaning stack, broken pallet, or loose banding, stop and fix it before anyone works nearby.

Unstable storage creates struck-by and crush hazards and forces people to take unsafe walking routes. Height is not the only factor; uneven ground, wind, vibration, and poor blocking can cause a small pile to fail. Keep heavy items low, rack or chock cylindrical items, and step back and key bagged products so they stay put. Use equipment for heavy bundles, never climb stacks, and never work with your body between a stack and a fixed object.

Keep stacks stable by racking, blocking, or interlocking

Stack heavy material low and lighter material higher

Set stacks on level, solid supports, and good pallets

Remove nails from used lumber before stacking

Keep pipe, bar stock, and round items blocked to prevent rolling

Step back, bag materials, and keep them keyed so they do not slide

Keep storage away from floor openings, hoistways, and unprotected edges

Post and follow floor load limits where required

Keep aisles and passageways clear and in good repair

Keep storage areas free of trip, fire, and debris hazards

Everyone owns storage safety. Before you walk away from a delivery, assess stability, blocking, and the stack’s position relative to travel paths and edges. Keep the storage area tidy so debris does not hide hazards and so you can see movement early. If a stack is questionable, do not try to catch it or straighten it by hand. Clear the area, get help, and rebuild it correctly.

What are two ways to keep a stack from sliding or collapsing

How should pipe and other round stock be stored to prevent rolling

What do you do when you find a leaning or unstable stack

Stack it solid, keep aisles clear, and prevent one preventable injury today.

Vibe code with your voice

Vibe code by voice. Wispr Flow lets you dictate prompts, PRDs, bug reproductions, and code review notes directly in Cursor, Warp, or your editor of choice. Speak instructions and Flow will auto-tag file names, preserve variable names and inline identifiers, and format lists and steps for immediate pasting into GitHub, Jira, or Docs. That means less retyping, fewer copy and paste errors, and faster triage. Use voice to dictate prompts and directions inside Cursor or Warp and get developer-ready text with file name recognition and variable recognition built in. For deeper context and examples, see our Vibe Coding article on wisprflow.ai. Try Wispr Flow for engineers.