THE ART OF LEADERSHIP

“Brilliant thinking is rare, but courage is in even shorter supply than genius.”

Peter Thiel

Courageous Decisions Beat Perfect Plans

Leaders rarely fail from a lack of ideas. They fail from hesitation: waiting for perfect data, perfect timing, perfect permission. Courage is choosing a direction while uncertainty is still on the table, then owning the consequences. When you act, you give everyone else a clearer signal than any memo can provide.

To lead courageously, make decisions as explicit bets. Define the objective, the trade-off you accept, and the risks you won’t tolerate. Invite dissent early, especially from the people closest to the work, then decide and communicate in one sentence. After that, do not reopen the call unless new evidence emerges.

Courage becomes a culture when it’s rewarded, not punished. Celebrate small experiments, fast escalation of problems, and clean post-mortems that focus on learning. Model calm under pressure, admit mistakes quickly, and give credit outward. Over time, your team stops waiting for certainty and starts building it.

Make one courageous decision this week: commit, communicate trade-offs, and review results in seven days.

COMMERCIAL CONSTRUCTION

What does selective project choice reveal about a builder’s standards?

AZ-Builds is a South Florida commercial construction company built on trust, quality, and results. Founded in 1981 as A-Z Blds Inc. by John Kurzman, the company later changed its name to AZ-Builds in 2016 under the leadership of president Steven Korfin and principal Andrew Yanowitz, and reported more than $50 million in completed projects.

The firm specializes in commercial buildouts for retail, restaurant, medical, office, and specialty spaces across Miami-Dade, Broward, and Palm Beach counties. Its promise is operational: meticulous planning, transparent communication, and delivery that stays on time and on budget.

What makes that promise believable is selectivity and advocacy. AZ-Builds says it carefully selects projects so every client receives full attention and white-glove service, then relies on trusted subcontractors while holding them to the same standards. Deep knowledge of permitting, budgeting, code compliance, and modern methods helps surface issues early and guide cost-effective decisions.

Selective focus plus transparent planning turns buildouts into long-term partnerships.

INFRASTRUCTURE INDUSTRY

Can early 30% designs prevent costly changes once construction starts?

A new design contract is setting the pace for the next rail segment in Southern California. Foothill Gold Line Construction Authority awarded Parsons Transportation Group a six-year, $60 million assignment to advance the project from about 30% design to approved-for-construction documents, and to provide design support during construction. It is the first of two major contracts under a construction manager-at-risk delivery plan. The work advances a 2.3-mile extension between Pomonaand Claremont that will extend the Metro A Line light rail system.

For contractors, the headline is not the designer; it is design maturity. CMAR only pays off when utilities, right-of-way, and systems interfaces are resolved early enough to bid packages with real quantities. Trackwork, traction power, signals, and station civil packages also compete for long lead electrical gear and specialty installers, so procurement timing becomes part of the schedule.

The most innovative teams treat the design phase as procurement. They push for early field verification, freeze key interfaces such as power feeds and communications rooms, and agree on acceptance tests before excavation begins. That discipline turns front-end planning into fewer change orders, tighter work windows, and a smoother opening day.

Treat design as procurement: freeze interfaces before buying long-lead gear.

RESIDENTIAL RESEARCH

Is drywall now the silent driver of housing affordability?

Interior finishes are becoming more expensive even as buyers remain payment-sensitive. A recent RSMeans-based update shows average interior construction costs up 6.8% year over year, with painting up about 10% and gypsum board up about 8%. Insulation is another pressure point, with the national average cost cited at $0.64 per square foot, up 19.14% year over year.

The data line up with broader price signals. Federal Reserve Economic Data shows the producer price index for gypsum building materials is still elevated through December 2025. Suppliers are also pushing targeted price increases, including a National Gypsum bulletin raising prices on PermaBASE cement board products, effective January 19, 2026, which affects shower surrounds and wet-area builds where substitutions are limited.

Builders can protect margins by treating finishes like a managed risk. Lock board and insulation packages earlier, tighten takeoffs to reduce waste, and keep approved alternates ready before rough-in. Standardize a smaller option set to reduce reorders, and sequence inspections to avoid rework that consumes extra drywall, mud, and paint. The win is not the cheapest spec; it is predictable lead times and fewer change orders.

Lock in finish packages early; small increases compound across all units.

TOOLBOX TALK

Powder-actuated fastening safety to prevent puncture injuries

Good morning, crew. Today, we will use fastening tools that fire pins with a powder charge. Treat them like a loaded gun. Only trained operators handle them, and everyone else stays out of the line of fire. Wear eye, face, and hearing protection. Verify that the base material is suitable and that no one is behind it. Load only when you are ready to fire, then unload before moving or setting it down.

These tools can send a pin through thin material, chip brittle surfaces, or ricochet when the base is too hard. A misfire can still discharge after a delay, so keep the tool pressed in place and follow the misfire procedure. Inspect the barrel, guard, and safety parts before use and test safety devices daily. Keep cartridges secure and never leave a loaded tool unattended.

Only trained operators use the tool

Inspect the tool, barrel, and guard before use

Test safety devices each day before loading per the manufacturer’s procedure

Wear eye, face, and hearing protection

Confirm the base material is acceptable, and check the opposite side for people or services

Keepyour hands clear of the muzzle and never point the tool at anyone

Load only immediately before firing and unload before walking or handing off

Do not fire into hard or brittle materials or into spalled areas

Avoid firing into thin or easily penetrated material unless backed to stop the fastener

If it misfires, keep it in place for 30 seconds, then unload per instructions and tag defects out of service

We will control the area, communicate before each shot, and stop if anything is uncertain. If the tool feels different, the surface is questionable, or the guard is missing, we do not improvise. Set it down, get the lead, and correct the setup. One careful minute prevents a penetrating injury that changes a life.

When should the tool be loaded, and when must it be unloaded

What is the immediate action and wait time after a misfire

Name two base materials or conditions where firing is prohibited

Every fastening shot is planned, controlled, and clear, so everyone leaves with zero injuries.

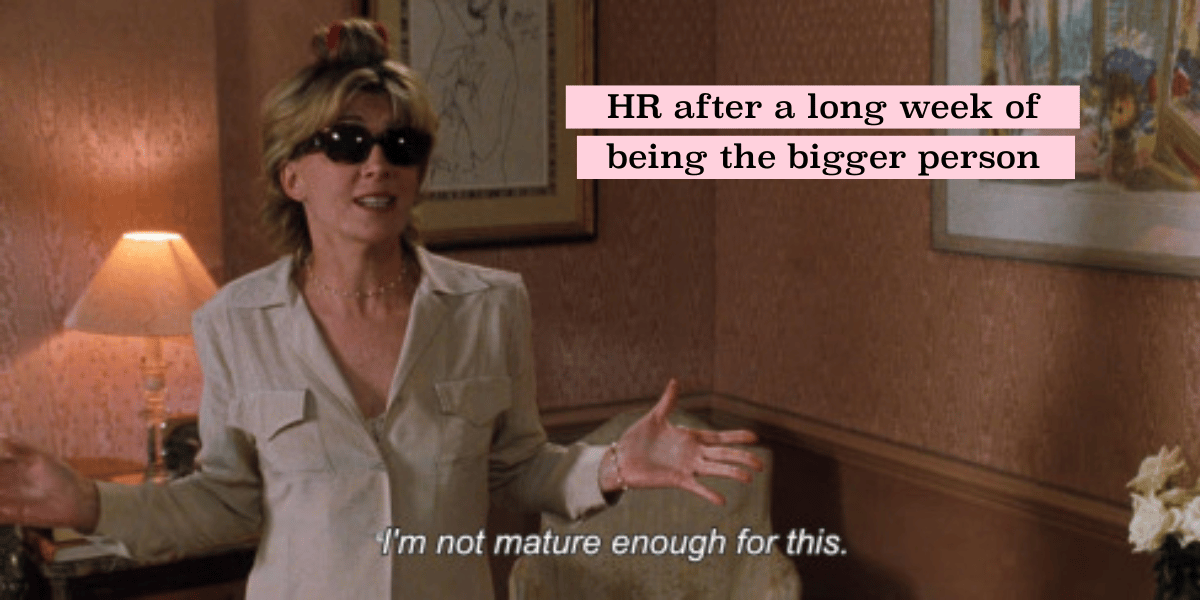

The best HR advice comes from those in the trenches. That’s what this is: real-world HR insights delivered in a newsletter from Hebba Youssef, a Chief People Officer who’s been there. Practical, real strategies with a dash of humor. Because HR shouldn’t be thankless—and you shouldn’t be alone in it.