“Clarity about what matters provides clarity about what does not.”

Cal Newport

THE ART OF LEADERSHIP

Clarity Creates Focused Teams That Finish What Matters

Leaders drown in input emails, requests, and meetings until everything feels equally urgent. Newport’s quote is a filter: when the team is clear on what matters, distractions become obvious. Without that clarity, people optimize for responsiveness, not results, and the day fills with motion that doesn’t move the goal.

Create clarity by choosing a small set of outcomes and writing them in plain language. Define what “done” looks like, the deadline, and the trade-offs you accept. Then make a stop-doing list and a decision rule: if a task doesn’t support the outcomes, it gets declined, delegated, or delayed.

Protect the focus with routines. Review priorities weekly, track one or two leading metrics, and keep meetings for decisions, not updates. Give people uninterrupted time to execute, and require new requests to name what they replace. Clarity isn’t a one-time announcement; it’s a habit that keeps attention pointed at the work that matters most.

Define the top three outcomes, remove one recurring distraction, and review progress every Friday for four weeks.

COMMERCIAL CONSTRUCTION

What turns a client-first motto into repeat business year after year?

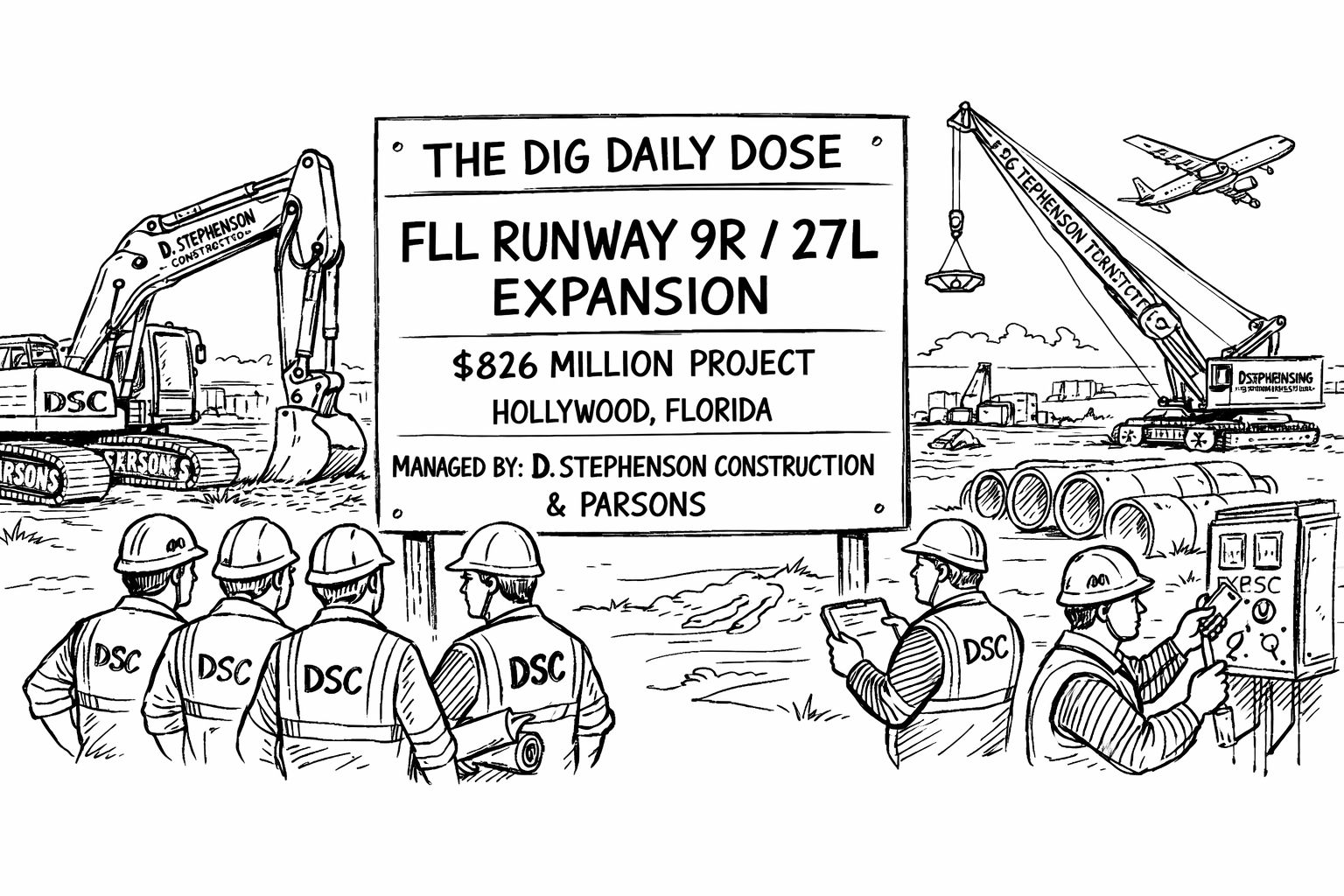

D. Stephenson Construction began in 1992 when Dinah and Dwight Stephenson set out to build a South Florida firm grounded in honesty and integrity. From Broward to Miami-Dade and Palm Beach, the company delivers construction management, program management, general contracting, and design-build, with a reputation for complex projects finished on time and within budget.

Its growth story is operational, not promotional. A carefully assembled team across construction and administration supports clients from offices in Fort Lauderdale, Miami, and Delray Beach. By learning each owner’s goals and baking them into daily decisions, DSC aims to make service feel unequaled, and it points to repeat clients as the proof that priorities are more than words.

Culture is treated as a lever for performance. DSC says it pairs high expectations with a family environment, rallying around the motto Build Like Champions. It values hard work, celebrates wins together, and speaks openly about faith and community support. The mission to enrich teammates and communities, and the vision to be a premier construction services firm, frame success as both results and relationships.

Client-first service and a team culture make complex delivery repeatable.

INFRASTRUCTURE INDUSTRY

Can a 10-foot crest beat endless dredging bills?

The U.S. Army Corps of Engineers just awarded a $35.9 million contract to Anvil Builders to raise the 184-foot Mount St. Helens Sediment Retention Structure by 10 feet. Construction is slated to start this summer and finish by October 2027, extending the dam’s ability to trap volcanic sediment and reduce downstream flood risk.

For heavy civil contractors, the job is more than adding dirt. You are rebuilding an operating flood control asset in a dynamic river system where material properties, moisture, and seepage control determine whether the raise will perform for decades. The real cost swing is in logistics: sourcing, haul routes, placement rates, and seasonal windows that protect fisheries and avoid high flows.

The insight is to manage sediment like inventory. Every cubic yard stored upstream is a cubic yard not dredged later, and that avoidedWorkk carries compounding savings for navigation and community protection. Owners and builders should track capacity burn, instrument the embankment, and align future dredging and levee work with measured sediment trends.

Spend early to trap sediment before it becomes a downstream liability.

RESIDENTIAL RESEARCH

When banks retreat, who funds the home buyers?

Bank money for homebuilding is getting tighter in early 2026, and it hits smaller builders first. NAHB’s chief economist notes that roughly two-thirds of homes are built by smaller, private firms that depend on bank construction and development loans, so that Fed rate cuts can lower their carrying costs. Yet on the ground, some South Texas builders say banks are still pulling back, pushing them toward private investors or even builder-funded starts.

The financing mix changes job-site decisions. Local reporting shows banks may finance only about 80% of a project, while private lenders can be more flexible but far pricier, with example rates around 13% versus about 8% at banks. Higher debt service makes every idle day hurt, so builders are standardizing specs, trimming option menus, and phasing releases to match presales and inspection capacity.

The practical play is to manage capital like a scope. Line up at least two funding paths, lock your takeout plan before you break ground, and keep contingency reserves for interest and delays. Standardize plan sets so lenders can underwrite quickly and track draws with clean photos, lien waivers, and updated schedules. If credit loosens later, you will already be ready to scale.

Diversify capital sources early; faster underwriting speeds protect your build calendar.

TOOLBOX TALK

Hand-arm vibration control when using powered tools

Morning, crew. Today, we will control vibration from breakers, compactors, and grinders. Vibration and cold can numb hands and reduce grip strength, increasing injury risk and causing long-term damage. Use the right tool, keep cutting parts sharp, and let the tool do the work. Rotate tasks, take short warm breaks, and report tingling or numbness in your fingers early so we can adjust.

Hand-arm vibration builds with time on the trigger. Early signs are tingling, white fingers, loss of feeling, and a weak grip, often worse in cold weather. Reduce exposure by using lower vibration tools, keeping handles tight, maintaining equipment, and holding with a light but controlled grip. Keep your hands warm and dry, as cold intensifies the effect. If symptoms start, stop and tell your lead.

Choose the right size tool for the task and material

Keep bits, blades, and wheels sharp and properly installed

Maintain tools so mounts, handles, and dampers are intact

Use the minimum grip force that still controls the tool

Do not press harder to go faster; let the tool work

Take short breaks and rotate tasks to reduce continuous exposure

Keep your hands warm and dry with proper gloves and spare pairs

Avoid smoking and stay hydrated to support circulation

Use correct posture and support the tool to reduce strain

Report tingling, numbness, or whitening of fingers and get evaluated

We prevent vibration injuries by managing time, tool condition, and body position. If you are losing feeling, you are losing control, and that is when cuts, drops, and pinch injuries happen. Break the cycle early with task rotation, warm breaks, and maintenance. Do not ignore symptoms or try to push through. Speak up so we can change the method, swap tools, or adjust the schedule.

Name two early signs of hand-arm vibration exposure

What are two ways to reduce vibration before relying on breaks

When should you stop and report symptoms during tool use

Limit vibration daily with sharp tools, rotation, and warm hands so everyone keeps a firm grip for life.

If You Could Be Earlier Than 85% of the Market?

Most read the move after it runs. The top 250K start before the bell.

Elite Trade Club turns noise into a five-minute plan—what’s moving, why it matters, and the stocks to watch now. Miss it and you chase.

Catch it and you decide.

By joining, you’ll receive Elite Trade Club emails and select partner insights. See Privacy Policy.