“Stay curious a little longer, rush to action and advice-giving a little more slowly.”

Michael Bungay Stanier

THE ART OF LEADERSHIP

Curiosity Beats Quick Answers in Every Conversation

Most managers default to solving, because answers feel efficient. But fast advice can shut down thinking and hide what’s really going on. Curiosity keeps you in discovery mode long enough to surface the real problem, the constraints, and the person’s ownership.

Use a simple sequence: ask “What’s the real challenge here?” then “And what else?” Pause. Summarize what you heard and ask what success looks like. Only then offer a suggestion, and frame it as an option: “One approach could be….” This keeps responsibility with them.

Make it routine. In 1:1s, require your own advice to come after at least two questions. In meetings, end by asking who will decide, what the next step is, and when you’ll review. The payoff is fewer escalations, better judgment, and a team that learns rather than waits.

Ask two questions before advising every conversation this week.

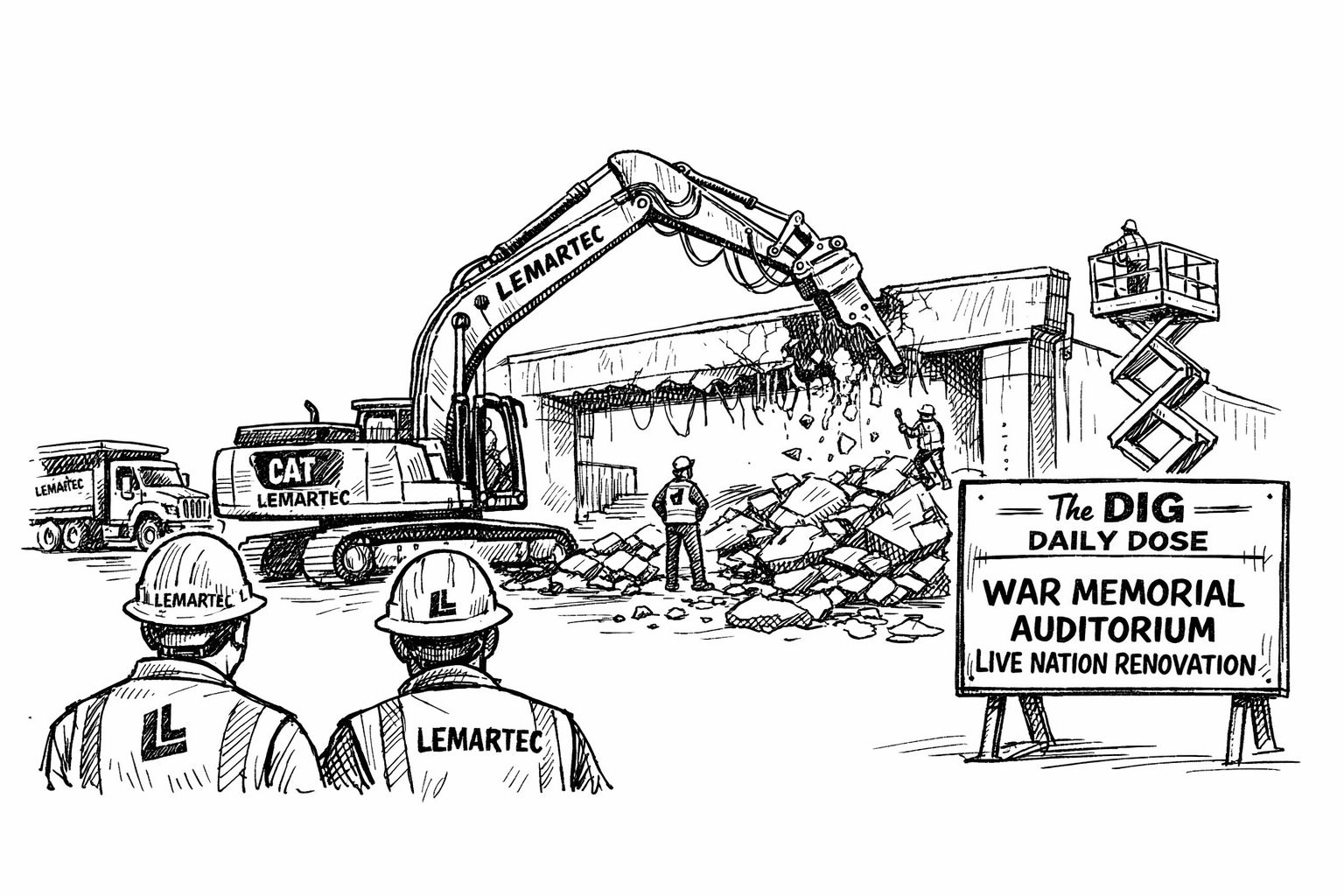

COMMERCIAL CONSTRUCTION

Can integration make complex projects predictable without losing human trust?

Lemartec presents itself as a national general contractor and construction manager, as well as MasTec’s vertical construction arm. It targets complex work across industrial, aviation, power, and large commercial markets, supported by strategic partnerships throughout the Americas and the Caribbean.

Its philosophy is that design and construction work best as one system. Lemartec emphasizes quality from preconstruction onward, leveraging value engineering, preconstruction services, and project controls to drive savings and provide clients with clear visibility throughout construction. It also positions a national client approach as a way to deliver consistent quality across an entire program, not just one project.

The company’s origin story reinforces that integrated mindset. Founded in 1979 by the Garcia-Tuñon family after Guillermo Garcia-Tuñon Sr. fled Cuba, Lemartec says it has carried forward family-rooted values with a safety-first, relationship-driven culture. It also highlights commitments to diversity and inclusion, sustainability through LEED involvement, and minority business leadership.

Lemartec reduces risk by pairing integrated design-build with safety-first, relationship-driven discipline.

INFRASTRUCTURE INDUSTRY

What keeps a megafab schedule from slipping before concrete is poured?

Micron will break ground on January 16 on its $100 billion megafab campus in Onondaga County, New York, after completing environmental review and securing key permits. The project is planned for up to four fabs and is pitched as a domestic memory manufacturing anchor for AI-era demand.

For infrastructure builders, the visible ceremony is just the handoff from paperwork to production logistics. The critical path starts with earthwork, stormwater, and ground improvement. Quickly becomes power and water: substations, feeders, backup generation, high-purity water, and wastewater capacity that must be online before the cleanroom fit-out can accelerate.

Execution risk clusters at interfaces. If utility milestones drift, contractors burn money on remobilization and idle specialty crews; if procurement misses, schedule compression turns into quality defects that fail commissioning. Owners and CM teams that standardize early packages, lock long lead equipment, and run disciplined change control will keep the project buildable even as designs evolve across phases.

Lock power, water, and permits before scaling construction.

RESIDENTIAL RESEARCH

How exposed is your schedule to the next metal price spike?

Copper prices hit fresh records in early January 2026, climbing above $13,000 per metric ton. The surge is being driven by supply disruptions at major mines and a scramble to secure material, while demand keeps rising from power infrastructure and AI-related data center buildouts.

Homebuilders feel this faster than most trades because copper is embedded in nearly every critical path decision. Electrical rough-in bids rise, panel and service upgrades become more expensive, and electrification features like EV-ready garages and heat pump systems increase copper demand. Higher prices also raise the stakes on lead times for electrical gear, where a late delivery can stall inspections and push closings.

The best defense is treating copper as a measurable scope, not a commodity you hope calms down. Track copper-heavy assemblies by plan, lock supplier quotes tied to delivery windows, and preapprove alternates where code allows, including layout changes that shorten runs. Order long-lead electrical components earlier, and set clear contract language for escalation so surprises do not land at trim.

Measure copper exposure early; lock prices before electrical rough-in.

TOOLBOX TALK

Temporary power safety with GFCI and cord inspection

Good morning, crew. Before we plug in today, we will control electrical shock hazards from temporary power and extension cords. Use GFCI protection or the site grounding program, and test devices as required. Inspect every cord and plug before use, and remove damaged cords from service immediately. Keep cords out of walk paths and away from water, sharp edges, and moving equipment. If anything looks questionable, stop and get it corrected.

Temporary power problems usually start small: a nicked jacket, a missing ground pin, a wet connection, or a cord pulled tight across traffic. Those minor issues can turn into shocks, burns, fires, and trips. The fix is discipline: inspect before use, protect cords from damage, keep connections dry, and never defeat safety devices. Electricity does not give a warning, so we rely on a consistent setup and immediate correction.

Use GFCI protection or the site-assured grounding program for temporary power.

Test GFCI devices per the site procedure and treat any trip as a stop-work signal.

Inspect cords, plugs, and tools before each use for cuts, exposed wire, or missing pins.

Remove worn or frayed cords from service and do not use until repaired or replaced.

Do not hang cords from nails, staple them, or suspend them with wire

Keep cords out of walkways and doors so they do not create trip hazards or get pinched

Keep connections off the ground and away from standing water, mud, and snow

Use the right cord size for the load and avoid overloading circuits and power strips

Protect cords at edges and openings so the jacket cannot be cut or crushed

Unplug by gripping the plug, not yanking the cord, and store cords to prevent damage

We will treat temporary power like a controlled system, not a convenience. If the setup is not correct, we fix it before work continues. Everyone has the authority to stop work if cords are damaged, missing protection, wet, or creating trip hazards. One good inspection and a clean setup prevent shocks and injuries that can end a career.

What are two defects that require a cord to be removed from service

What should you do immediately if a GFCI trips during use

Why is it unsafe to run cords through doorways or across walk paths

Inspect every cord, use GFCI protection, and stop work before a shock can happen.

Stop guessing. Start scaling.

See the top-performing Facebook ads in your niche and replicate them using AI. Gethookd shows you what’s actually working so you can increase ROI and scale ad spend with confidence.