“You do not rise to the level of your goals. You fall to the level of your systems.”

James Clear

THE ART OF LEADERSHIP

Stop Relying on Motivation, Build Repeatable Routines That Make Results Inevitable

Goals are functional for direction, but they rarely survive busy weeks, shifting priorities, or low energy. The gap is the process: what happens on ordinary days when nobody is watching. When the routine is vague, progress depends on motivation, and motivation is unreliable. A dependable routine turns intention into output.

Start by shrinking the change to a repeatable action you can do even on your worst day. Decide the trigger (After the daily stand-up), the action (I spend 10 minutes updating the project board), and the finish line (until the top three priorities are clear). Make the correct action the default: templates, checklists, calendar blocks, and fewer choices.

Review weekly. Track the behavior, not just the outcome: number of updates, responses within 24 hours, blocked items removed. If the routine breaks, adjust the environment, reduce steps, add reminders, pair with a colleague rather than blaming effort. Consistency compounds, and the standard you repeat becomes the result you get.

Create one daily ritual, track it for 14 days, and adjust the environment to make it easy.

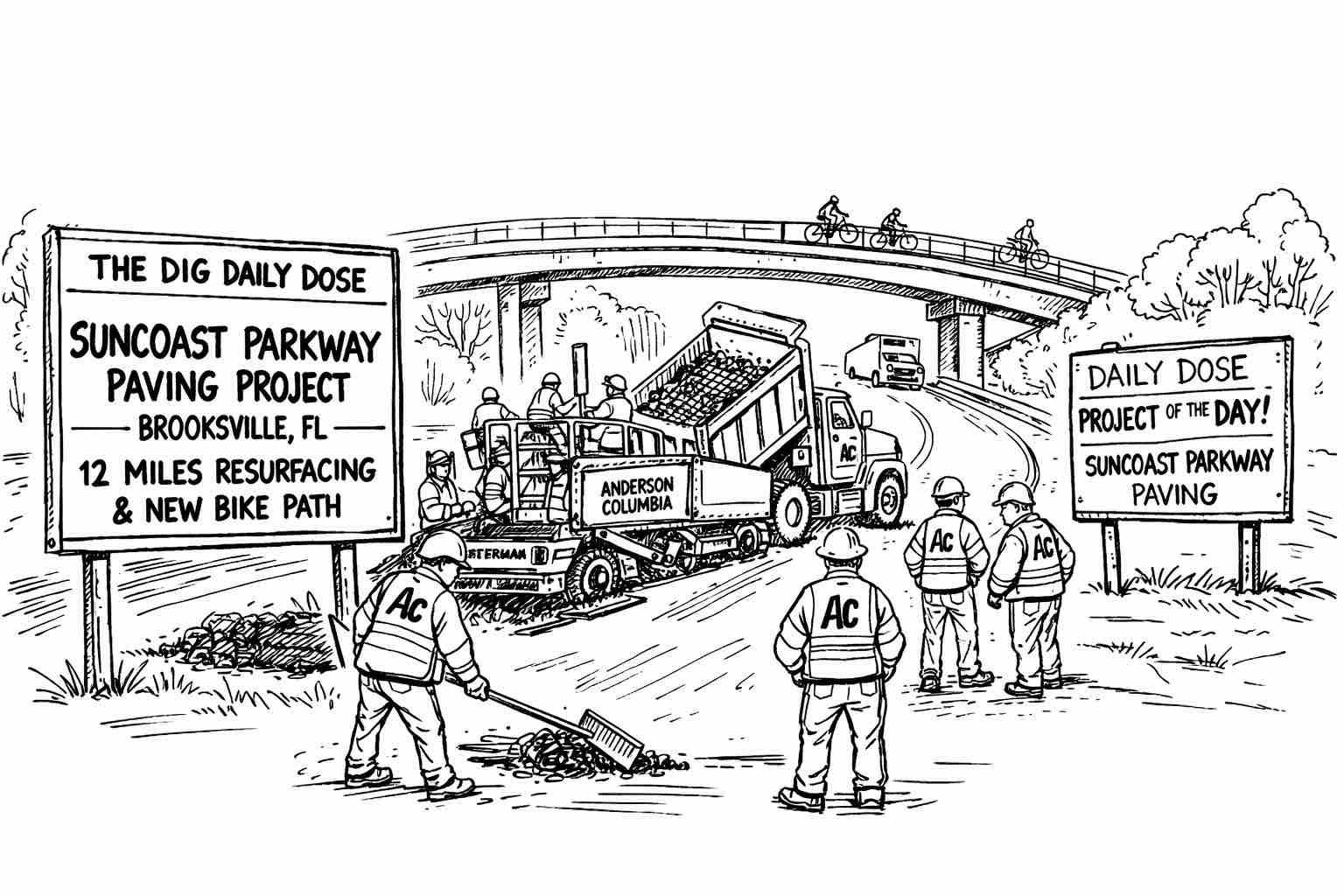

COMMERCIAL CONSTRUCTION

What makes a road feel like trust, not just pavement?

Anderson Columbia frames infrastructure as the “fundamentals of America,” the quiet systems that enable commerce and daily life. Roads, bridges, and paving are treated not as commodities, but as public promises: build efficiently, keep costs responsible, and still deliver a smooth ride with a clean, durable finish.

That promise is backed by repetition at scale. As one of the Southeast’s most significant highway construction firms, the company says it has built or rehabilitated thousands of miles of highways and streets across Florida, Georgia, and Alabama, delivering on time and within budget. Its service mix, from asphalt paving and bridge building to dredging, design-build, general contracting, and mining, suggests a builder designed to stay useful across changing scopes.

The most persuasive edge is control. By operating its own asphalt plants, many of them mobile, Anderson Columbia can protect material quality while meeting deadlines, then extend the same discipline to the small but critical details: moving earth, pouring concrete, or installing accessible ramps. In that view, quality, timeliness, and safety aren’t slogans; they’re the mechanisms for trust.

Control materials and details, and infrastructure becomes a reliable public promise.

INFRASTRUCTURE INDUSTRY

Can early approvals keep pace with power demand and execution?

Duke Energy has asked the Nuclear Regulatory Commission to approve an early site permit near Belews Creek in North Carolina, locking in a location well before a final reactor choice. The company says it could add about 600 megawatts by 2037, with a first unit in 2036, as data centers and electrification rewrite demand projections.

For contractors, that front-loaded decision shifts work toward geotechnical drilling, water and cooling studies, transmission tie-ins, and early constructability. It also pulls nuclear-quality expectations into everyday trades, such as concrete placement, rebar traceability, welding procedures, and documentation that can withstand audits years after the pour.

The insight is that early certainty only helps if procurement and interfaces mature at the same pace. Modular suppliers, heavy lift logistics, and commissioning sequences need to be mapped while the permit file is still open, not after award. Builders who invest early in compliance workflows and partner with specialty vendors will be positioned when the project finally converts from planning to execution.

Start nuclear quality workflows before bids turn into mobilization.

RESIDENTIAL RESEARCH

How often do closings fail because flood coverage isn’t bindable?

After months of renewal uncertainty, a House committee advanced an extension that would keep the National Flood Insurance Program running through September 30, 2026, retroactive to September 30, 2025. In coastal and river markets, this eliminates a recurring closing risk, as many lenders require active coverage before funding.

When a lapse looks possible, transactions pause, buyers hesitate, and builders carry finished inventory longer. Projects in mapped floodplains can see contracts fall apart, draws delayed, and inspections rescheduled as paperwork stalls. Even homes outside high-risk zones can get pulled in when flood maps update or prior claims surface.

Builders can use the breathing room to tighten execution. Flag flood zone lots at acquisition, price elevation, and drainage early, and start insurance shopping at pre-sale instead of at final walkthrough. Document mitigation features for underwriters, coordinate surveys on base flood elevations, and keep backup lenders ready when requirements differ.

Start flood zone diligence early; insurance timing can make or break closings.

TOOLBOX TALK

Prevent dropped objects from overhead work today

Good morning, crew. We will control the risk of items falling from height. Set an exclusion zone below, keep hard hats on, and secure tools and materials before you start. Use tool lanyards when you are on ladders, lifts, or scaffolds. Do not stage loose parts near edges. If something must be handed up or down, use a bucket and a tag line, not pockets. If you see an unprotected edge or clutter, stop and fix it.

Falling items often come from routine actions: setting a tape on a ledge, leaving bolts on a plank, or moving materials in the wind. A small object can seriously injure someone below, even with head protection. The controls are planning and discipline: keep the area below clear, secure what you use, and store what you do not. Treat every edge like it will vibrate, shift, or get bumped, and keep your work platform organized.

Establish a no-entry zone under elevated tasks and enforce it

Wear hard hats anytime you are in an active work area

Use tool lanyards for hand tools when working at height

Keep materials and tools away from edges and openings

Use toe boards, screens, or netting where items could fall

Do not carry loose hardware in pockets; use pouches with closures

Lift and lower materials with containers, not by tossing or hand passing

Secure plywood, lids, and light materials when the wind can move them

Maintain housekeeping on the scaffold and platforms, clear scrap and loose parts

Stop work if people must pass below, reset the zone, and communicate

We protect each other by controlling what can fall and who can be below. Take one minute to set the zone, secure your tools, and clean your platform before you start and as you move. If you drop anything, call it out immediately and check for injuries and hazards before work resumes. A clean platform and a controlled area below keep the whole crew safe.

What is the first control you set up before starting work at height

Name two ways to prevent tools from falling while you work

What should you do if someone needs to pass through the exclusion zone

Zero drops: secure every tool, control the zone, and protect everyone below.