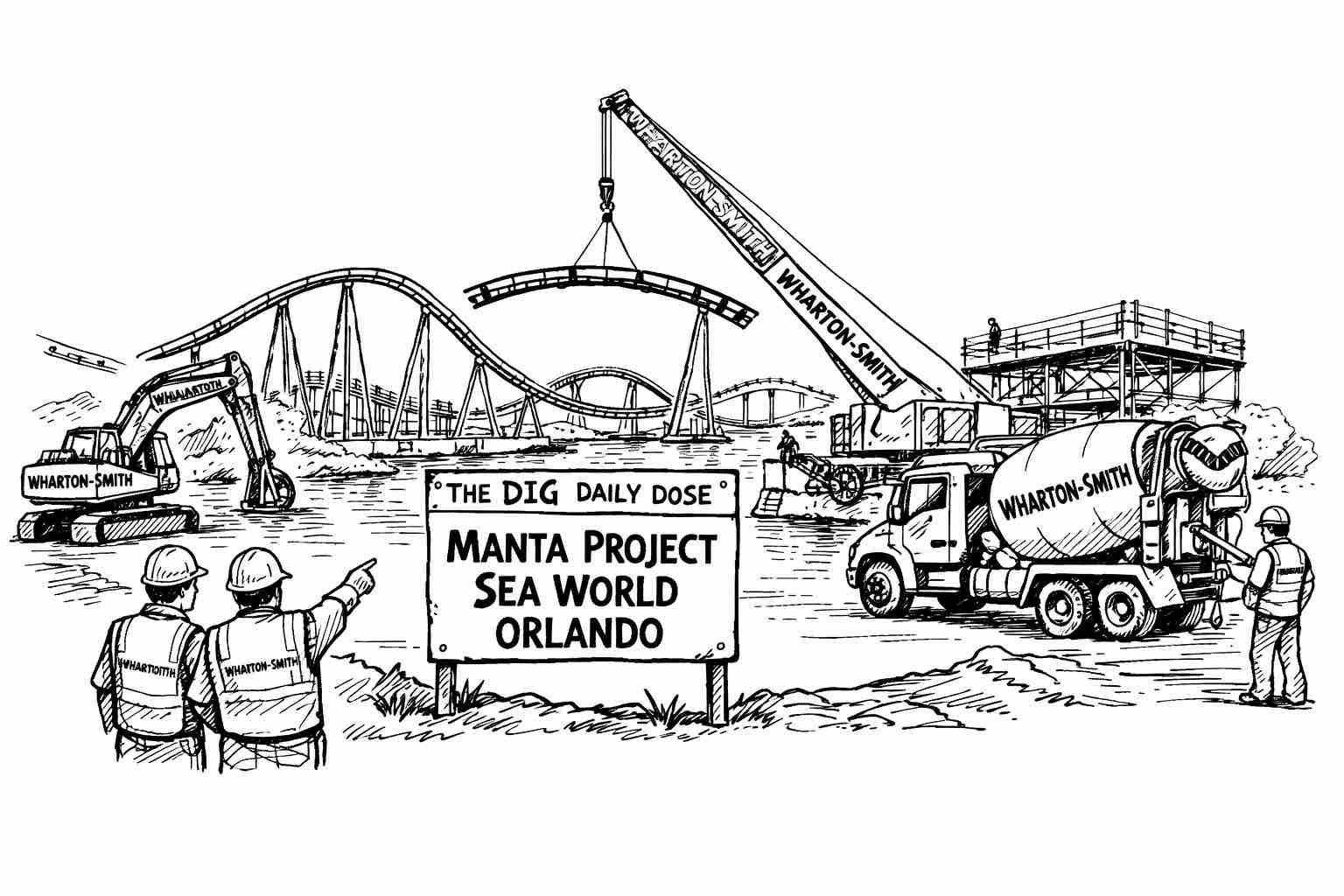

Wharton-Smith is a construction manager and general contractor focused on building communities through clean water systems and municipal facilities, as well as schools, public safety stations, parks, and hospitality projects. Backed by decades of experience, the firm turns complex civic needs into durable places that serve people well.

“All decisions are bets.”

Annie Duke

THE ART OF LEADERSHIP

Treat Every Choice Like a Bet and Improve Your Odds

When outcomes are uncertain, the temptation is to judge yourself by results. But a lucky win can follow a sloppy process, and a smart call can still fail. Thinking in bets shifts the focus to what you controlled: the information you had, the options you considered, and the probability you assigned.

Before committing, define the bet in one sentence: what you’re risking, what success looks like, and what would change your mind. Ask, “What evidence would prove me wrong?” Then look for that evidence on purpose through data, dissenting voices, or a quick experiment. This reduces confirmation bias and makes you less attached to being right.

After the decision, run a brief review that separates the process from the outcome. If you’d make the same choice again given the same facts, the process was sound even if the result stung. If you got a good result from weak reasoning, treat it as a warning. Over time, better bets compound into better performance.

Write your next decision as a bet, assign odds, and schedule a review.

COMMERCIAL CONSTRUCTION

How does Wharton-Smith keep integrity practical as it grows?

Wharton-Smith’s origin story is unusually concrete: two Ohio coworkers, George Smith and Bill Wharton, came to Central Florida when their employer opened a Florida office in 1975. When that company planned to move back north, they took over the unfinished work and, on April 2, 1984, incorporated Wharton-Smith with just a handful of employees.

Today, it positions itself as a general contractor, construction manager, and design-build partner offering preconstruction and green building services. Headquartered in Sanford, Florida, it operates full-service regional offices across Florida, including Charlotte, Baton Rouge, Houston, and Gulfport, and is supported by roughly 680 construction professionals. The firm also highlights recognition as an ENR Top 400 contractor, signaling both scale and repeatable process.

Its project portfolio reads like local life support water and wastewater treatment, schools, public safety facilities, parks, arenas, themed attractions, churches, senior living, medical offices, and hotels. The throughline is cultural: a stated mission to exceed client expectations through quality, professionalism, and fairness, backed by core values of honesty, integrity, trust, and quality. Meticulous planning, continuous training, and shared standards turn those values into fewer surprises and better partnerships.

Wharton-Smith turns regional scale into predictable delivery through values, planning, and skilled teams.

INFRASTRUCTURE INDUSTRY

Does the firm offtake end construction risk or merely reprice it?

A new binding sales deal is giving the Gulf Coast export more certainty. Woodside said it will supply Turkey’s state buyer, BOTAS, with about 5.8 billion cubic meters of product over up to 9 years starting in 2030, with volumes sourced mainly from its Louisiana complex, now under construction. The facility received final approval in April and is slated for first gas in 2029.

For the construction business, a contract like this matters as much as a permit. Long-duration projects live or die on bankable revenue, and lenders want proof that capacity will be used before they tolerate cost risk. Once buyers sign, owners can commit to early procurement of long-lead equipment such as compressors, cryogenic tanks, and power systems, rather than waiting until drawings are perfect.

The insight is that offtake does not remove risk; it relocates it onto delivery discipline. If the commercial clock starts in 2030, every late module, labor bottleneck, or commissioning failure becomes a financial event, not just a schedule headache. Strong builders will lock interface scopes early, tie payments to tested milestones, and plan logistics through ports and pipelines to ensure a predictable handover.

Secure long-term buyers before locking EPC schedules and procurement.

RESIDENTIAL RESEARCH

Can smarter permitting cut costs faster than cheaper financing?

One Bay Area market is showing how permitting can become the most significant cost driver. In the San Jose metro, multifamily permits fell 41% year over year through July, and local leaders are trying to reverse the slide by tightening review timelines, digitizing submittals, and piloting software that flags application issues before staff ever touch a file.

For builders, the value is fewer surprise corrections. An automated precheck can catch missing sheets, inconsistent square footage, and common code mismatches that trigger weeks of back-and-forth. That shortens carrying costs, keeps subcontractors from being rescheduled, and makes lenders more comfortable funding starts on predictable timetables. The risk is overreliance, so agencies are keeping humans in the loop and using the tool as an assist, not an approval stamp.

The competitive edge will go to teams that build for the review process. Standardize plan sets, submit cleaner calculations, coordinate early with utilities, and keep alternates ready when a design choice trips a rule. In San Jose, a new streamlined ministerial pathway has already enabled a large mixed-use project to be approved in eight months, a timeline that used to take up to two years.

Submit cleaner plans; permit speed saves more than price cuts.

TOOLBOX TALK

Trench cave-in prevention and safe access

Morning, crew. Today, we are working around open excavations, so we will treat every trench as if it can collapse without warning. The competent person will inspect before entry and after any change in weather or conditions. No one enters unless the protection, access ladder, and spoil placement are correct. Keep tools and materials back from the edge, and stay clear of suspended loads. If you see cracks, water, or sloughing, call stop work.

A cave-in can bury a worker in seconds, even during short tasks. Soil changes with moisture, vibration, and nearby traffic, so yesterday’s conditions may not hold today. Use the planned protective system and never climb into an unprotected excavation. Keep ladders in place, maintain clear communication with operators, and avoid working beneath loads or buckets. Good housekeeping reduces slips that put people against an unsafe wall.

A competent person inspects before entry and after rain, freezing, or other changes.

Do not enter if protective systems are missing, damaged, or not installed correctly.

Keep spoil piles, materials, and equipment back from the edge

Provide safe access and exit with a ladder or ramp in reach

Keep the ladder tied off and extending above the landing point

Watch for cracks, bulges, sloughing, and falling material at the face

Control water and stop work if water is accumulating or seeping in

Keep people out when equipment is loading, swinging, or dumping near the edge

Barricade the area to prevent falls and keep traffic away from the cut

If you are unsure, stop and ask before anyone goes in

Our standard today is simple: inspection, protection, and safe access before entry, every time. If the excavation looks different, if water shows up, or if the protective system is disturbed, we stop and fix it. Nobody will be pressured to enter. We would rather lose five minutes resetting the setup than lose a coworker. Speak up early, and we will adjust the plan.

Who decides if an excavation is safe to enter today

Name three warning signs that mean everyone exits immediately

What must be in place before anyone climbs down into the cut

No one enters until it is protected, inspected, and a ladder is in place.