Radical Candor is what happens when you care personally and challenge directly.

Kim Scott

THE ART OF LEADERSHIP

Caring feedback turns friction into growth and keeps teams moving forward.

Teams don’t fail from a lack of talent as often as they fail from a lack of honest communication. When people avoid tough conversations, minor issues harden into patterns, trust erodes, and performance plateaus. Leaders raise standards by making truth safe to hear.

The key is pairing directness with genuine care. Be specific about what you observed, explain the impact, and focus on the next step rather than the person’s character. When people feel respected, they can accept discomfort without feeling attacked, and feedback becomes guidance instead of a threat.

Over time, this habit creates a culture where improvement is expected. People ask for input earlier, correct course faster, and stop wasting energy on guesswork. The result is a stronger team that can move quickly, learn publicly, and keep getting better without breaking relationships.

Give one piece of clear, caring feedback each day to strengthen performance and trust.

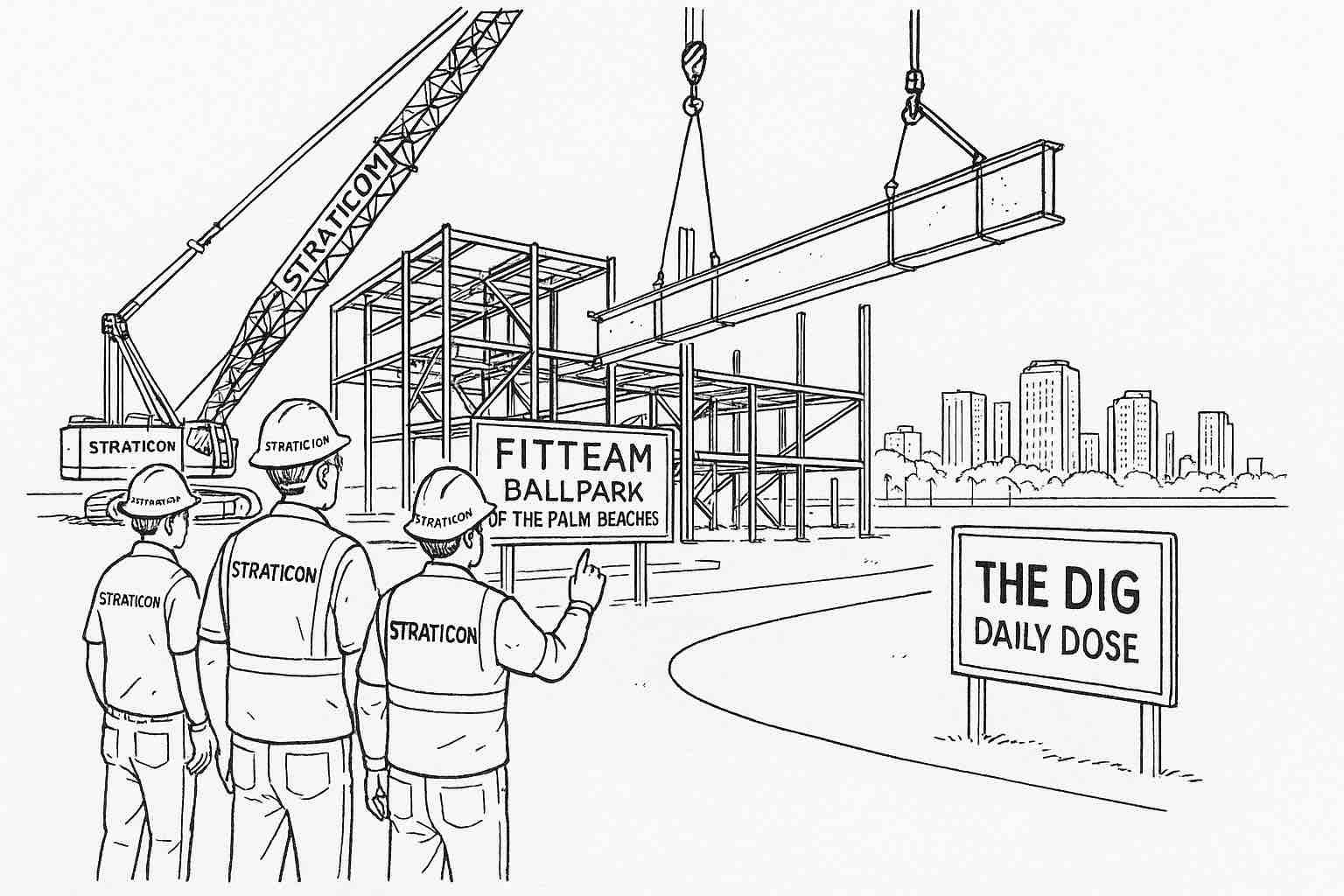

COMMERCIAL CONSTRUCTION

What does a better building mean beyond the finished structure?

Straticon’s idea of a better building starts before concrete is poured. It emphasizes the steps along the way, from planning and coordination to anticipating variables so the finished result feels earned, not accidental. For more than 30 years, it says it has worked one step ahead to become one of the top contractors in South Florida.

Scale reinforces that claim. Straticon reports completing 280 projects valued at over $3 billion and winning eight industry awards. Its experience spans nearly every product type, with special focus on hospitality, multifamily, country clubs, marinas, commercial work, renovations, and luxury residential.

The company also frames its growth as a series of deliberate pivots. It traces its start to a collegiate painting business founded in 1991, followed by a relocation to South Florida and projects for clients such as The Related Group, The Trump Organization, and BlackRock. With a 2020 headquarters move to Boca Raton, the throughline is clear: protect client satisfaction by staying proactive as the market evolves.

Better buildings come from proactive planning, broad expertise, and client-driven growth.

INFRASTRUCTURE INDUSTRY

What happens when inventory truth controls construction funding rather than promises?

Recent headlines show drinking water programs tying more money to verified pipe inventories, pushing cities to prove where old service lines actually are before crews ever break ground. That shift changes the rhythm of work from grant chasing to readiness building, because the next dollar increasingly follows the best data.

For contractors, the constraint is less about excavation and more about execution discipline. Successful teams will package neighborhoods into repeatable work zones, coordinate shutoffs with minimal disruption, and secure materials and traffic control early. The best bidders will also help owners manage the human side: door-to-door notices, quick restorations, and a clear plan for unexpected finds under the street.

The bigger insight is that this trend rewards utilities that treat mapping and records as part of the build. When inventories are credible, projects can be scoped faster, priced more accurately, and sequenced to protect vulnerable residents first. When inventories are shaky, every surprise becomes a schedule slip, a change order fight, and a reputational hit.

Inventory accuracy is now a construction strategy, not just paperwork.

RESIDENTIAL RESEARCH

Will plan-reading automation speed up homes without shrinking quality oversight?

Plan reading automation is suddenly at the center of preconstruction talk, promising to turn messy PDFs into clean takeoffs and draft budgets almost instantly. In a business where a single estimator can bottleneck dozens of starts, anything that compresses bid time becomes competitive leverage.

For residential builders, the upside is less guesswork and fewer expensive surprises. Faster quantity checks can tighten purchasing, help schedule trades earlier, and reduce the friction that triggers change orders. The downside is that speed can encourage overconfidence, and quicker bids can start a race to the bottom that punishes careful contractors.

The smart move is to treat these tools like a calculator, not an autopilot. Compare outputs to past jobs, require field leads to validate assumptions, and track the estimate-to-actual variance by trade. If the numbers drift, fix the process before you chase more volume.

Use automation to generate estimates, then verify against field reality.

TOOLBOX TALK

Preventing dropped objects and falling materials from elevated work

Good morning, crew. Today, we are focusing on avoiding tools and materials from falling from lifts, scaffolds, and edges. One dropped item can seriously injure someone below.

Dropped objects occur when tools are left near edges, materials are poorly stacked, or hands slip during movement. Wind, vibration, and distractions make it worse. Use toe boards, tool lanyards, secured storage, and controlled access below elevated work. Clear communication and exclusion zones protect everyone working underneath and keep the site moving without incidents.

Keep toe boards and guardrails installed on platforms and scaffolds.

Use tool lanyards when working from lifts, ladders, or scaffolds.

Do not store tools or materials on guardrails or near open edges.

Secure loose items, such as bolts, pins, and fasteners, in closed containers.

Stack materials stably and never above safe heights on platforms.

Barricade and post exclusion zones under overhead work.

Never work under suspended loads or while materials are being hoisted.

Keep your hands clear when receiving loads and avoid sudden movements.

Account for wind and stop work when items can be blown or toppled.

Perform a final sweep before moving lifts or leaving elevated areas.

Overhead hazards are shared hazards. Protect the people below by securing everything above, keeping zones clear, and speaking up if protections are missing. A clean, controlled platform prevents a life-changing incident in seconds.

What controls should be in place before anyone works on the overhead activity below?

When should you use tool lanyards and secured containers for small parts?

What steps will you take before leaving an elevated platform or moving a lift?

Today, we secure every tool and material at height and keep the ground zone below completely protected.