Leadership is not about titles, status, and wielding power. It’s about one life influencing another.

Brené Brown

THE ART OF LEADERSHIP

Lead with courage by choosing influence, empathy, and shared responsibility.

When we see leadership as influence rather than rank, our focus shifts outward. The question changes from how to gain power to how to leave people stronger. Every interaction becomes a chance to model courage, listen deeply, and help others see possibilities they cannot yet see.

This perspective demands humility. Instead of hiding behind titles, we step into conversations that feel uncomfortable but necessary. We ask for feedback, admit our mistakes, and invite others to challenge our assumptions. In doing so, we build trust that cannot be commanded; it can only be earned through consistency.

Leaders who choose influence over status create environments where people dare to contribute fully. Team members speak honestly about risks and opportunities because they feel respected, not judged. Over time, this shared courage turns ordinary groups into communities capable of innovation, resilience, and meaningful, sustainable results.

Practice influence through service, empathy, and courageous conversations in every leadership interaction.

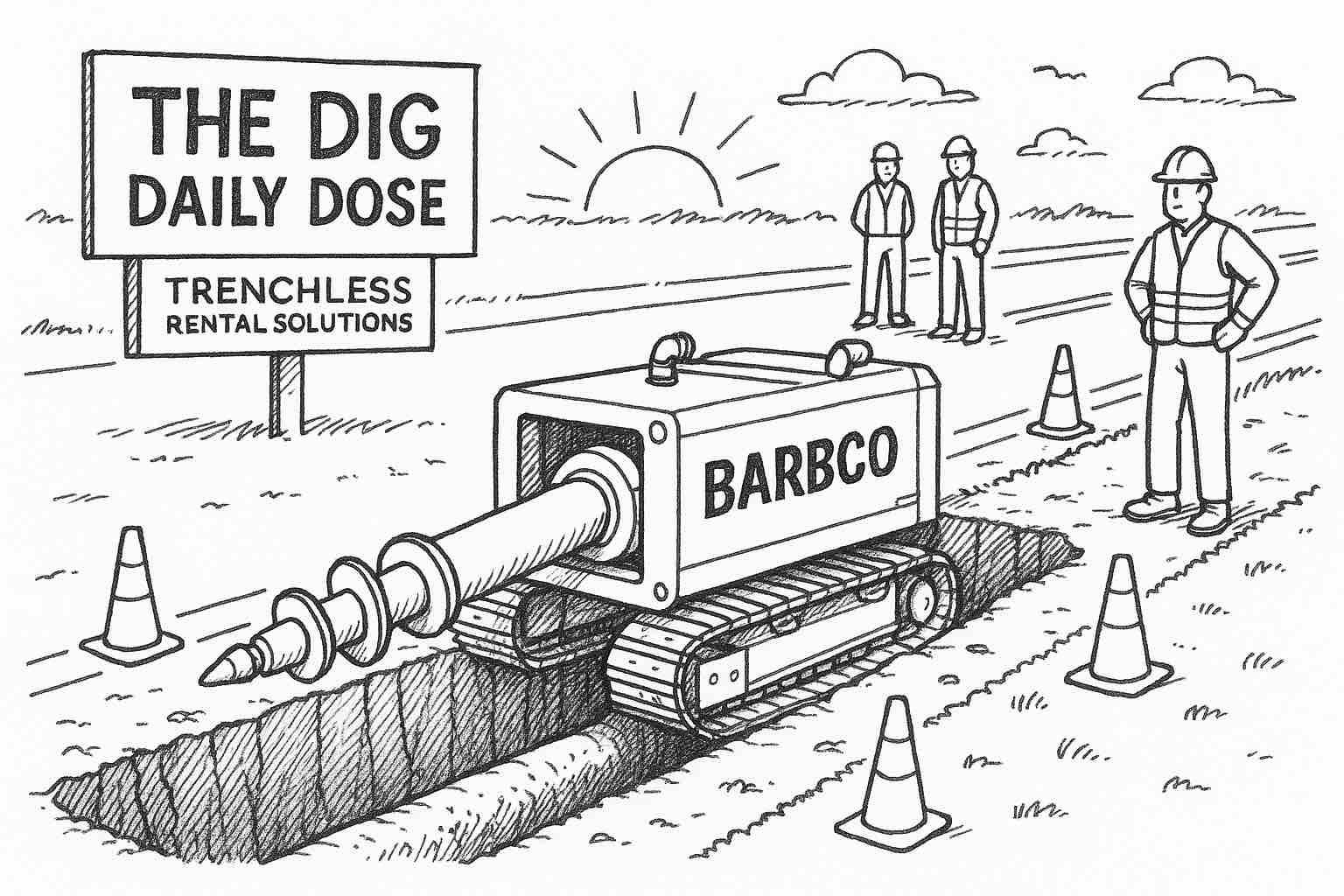

COMMERCIAL CONSTRUCTION

How does TRS turn trenchless equipment access into a strategic contractor advantage?

Trenchless Rental Solutions sits at the intersection of risk and reliability in underground construction. Instead of forcing contractors to own every machine, TRS rents and sells specialized boring and drilling equipment so crews can match tools to projects, not budgets, timelines, or what happens to be in the yard.

That flexibility is backed by service, parts, and refurbishments designed to extend the life of every asset. Factory-direct components, experienced technicians, and the ability to revive older machines mean contractors can keep existing fleets productive while still accessing newer, application-specific technology when a job demands it.

Because TRS partners with established manufacturers and industry associations, its catalog reflects both innovation and proven methods. Accessible financing, clear quoting, and nationwide reach allow smaller firms to bid confidently on demanding trenchless work, turning what once felt like specialized, high-risk projects into repeatable, profitable parts of their business.

Specialized rental, service, and refurbishments turn complex underground work into manageable, profitable projects.

INFRASTRUCTURE INDUSTRY

What does the ballooning rail cost reveal about contractor risk?

A showcase desert rail line between Las Vegas and Southern California has seen its price tag soar from roughly $8 billion to more than $21 billion. Higher material costs, intense competition for skilled labor, and tighter environmental regulations are reshaping budgets. At the same time, crews prepare for years of grading, bridge work, and station builds along the interstate median.

For builders, the escalation is both a warning and a leverage. Design-build teams must protect margins against fluctuating steel, concrete, and borrowing costs, even as investors and federal backers demand firm guarantees on schedule and performance. Misjudged bids could trap contractors in a decade-long project where every delay erodes profit.

Public sponsors face their own credibility test. Communities want congestion relief and union jobs, but also proof that extraordinary costs deliver long-term value and climate benefits. The teams that thrive will be those that share data early, reprice risk transparently, and keep revisiting phasing and scope rather than pretending a first cost estimate was destiny.

Price volatility makes flexible contracts and contingencies as vital as engineering.

RESIDENTIAL RESEARCH

How will immigration crackdowns reshape who builds American homes?

Stepped-up immigration enforcement is rippling through residential job sites, where contractors report their worst labor shortages in years. National surveys show most builders struggling to fill openings, with many delaying or resizing projects because key crew members have vanished or fear workplace raids. Slower framing and finishing work are now primary reasons buyers wait longer for move-in dates and face unexpected cost escalations.

Immigrant workers make up roughly a quarter of the construction labor force, concentrated in physically demanding trades such as concrete, framing, roofing, and drywall. When those crews shrink, raising wages alone cannot instantly replace years of skill and experience. Builders end up bidding against one another for scarce hands, which pushes project budgets higher and nudges entry-level homes further out of reach for first-time buyers.

States and cities are scrambling to respond with accelerated training programs, apprenticeships, and outreach to keep lawful workers in the field. Yet these fixes move more slowly than federal policy shifts. Many residential builders now argue that stable, predictable immigration rules and targeted visas for construction trades are as crucial to housing affordability as interest rates or zoning reform.

Support sensible labor policy to keep housing supply and timelines stable.

AI is all the rage, but are you using it to your advantage?

Successful AI transformation starts with deeply understanding your organization’s most critical use cases. We recommend this practical guide from You.com that walks through a proven framework to identify, prioritize, and document high-value AI opportunities. Learn more with this AI Use Case Discovery Guide.

TOOLBOX TALK

Staying safe around heavy equipment and moving vehicles

Good morning, crew!

Today, we’re focusing on how we work around machines, trucks, and loaders. One bad move near equipment can be life-changing, so we need clear communication, attention, and separation from moving gear at all times.

Working near equipment is one of our highest-risk tasks. Most serious injuries happen when people enter blind spots, walk behind moving vehicles, or assume the operator sees them. Use eye contact, signals, and set boundaries so people and machines never compete for the same space.

Stay out of blind spots; make eye contact with operators before approaching.

Never walk or stand under raised loads or buckets.

Keep a safe buffer distance from swinging or rotating equipment parts.

Use spotters when backing or maneuvering in tight or congested areas.

Wear high-visibility gear so operators can see you quickly.

Only authorized, trained people operate equipment; no riders on steps or buckets.

Use designated walkways and crossings instead of cutting through equipment zones.

Park the equipment on level ground with the brakes set and the attachments lowered.

Report malfunctioning horns, lights, alarms, or mirrors immediately.

Avoid distractions such as phones near moving equipment; stay alert and predictable.

When people and machines work together with clear rules, we reduce the chance of struck-by incidents and keep production moving smoothly. Look around your current work area and adjust routes, barricades, or spotters before equipment starts up.

What are three ways workers can be struck by or pinned by equipment here?

Where are our highest-risk blind spots or pinch points on this site?

What steps must you take before entering an area where equipment is operating?

Today, we control how people and machines interact, so everyone goes home uninjured and confident.